-40%

Capt. Don #2 Stainless Steel Boat Boom Brake - Sail With Confidence

$ 31.67

- Description

- Size Guide

Description

The Capt. Don #2 Stainless Steel Boom Brake.If your traveler shackle bolt is 1/2" diameter or less then we are confident this will be strong enough for your boat. The #2 is a heftier version of the original Capt.Don's and are used on boats up to and including the 50 foot range. We still have a few original Capt. Don's. If you would like one, please make an offer of and specify that you would like the original.

A boom brake takes far less loading than the traveler.

Over 1000 units are now sailing the world, saving lives, equipment and marriages. Accept no substitute.

As seen in

http://www.sailingtoday.co.uk/gear/gear-on-test/boom-brakes-group-gear-test/

SAIL magazine Dec 2016 on page 22

Recommended by

Practical Sailor

July 2017

Please avoid purchasing knockoffs of this item on eBay and elsewhere as they infringe on our copyrights and substantially harm our business.

Safety first, right? We have flares, life jackets, EPIRB's, life rafts, etc. but why not a boom brake?

A boom brake is a great device for controlling the boom swing during an intentional or unexpected gybe and a critical safety device when sailing downwind, in poor conditions, at night or short handed. It reduces your work load, stress on your rig and it could save someone's head or life.

See the video of use on a Bristol 32:

http://youtu.be/yCkFUGl12xw

Complete parts list and larger images of the above Bristol 32 installation.

Boom safety concerns

(

http://en.wikipedia.org/wiki/Boom_%28sailing%29

)

The second leading cause of death on sailboats is directly attributed to the use of booms. (This is backed up by

research

from Andrew Nathanson, MD, an emergency physician who is conducting a worldwide study on sailing injuries)

[2]

Booms can cause injuries directly, sweep people overboard, and their associated hardware and lines represent tripping hazards. On larger boats, sailors tend to stand on the boom to perform sail maintenance and install or take off sail covers. Falls from the boom onto the deck below occur. Even when stationary, booms represent a hazard since on most boats there is insufficient headroom to walk below them without ducking. According to a German study, "boom strikes were the most common cause of serious sailing injury overall".

[3]

When boom injuries occur far from shore they can require expensive rescues. In 2010 the US Coast Guard and Air National Guard utilized a

Lockheed C-130 Hercules

aircraft to rescue a man from 1400 miles off the Mexican coast.

[4]

Deaths and injuries can occur on boats operating upon lakes and coastal waters.

[5]

[6]

[7]

[8]

Boom related accidents can also imperil the remainder of the passengers and crew aboard when a key member is lost as occurred in April 2011.

[9]

As a precaution, any sailboat with a low boom should mandate use of

life jackets

, and ensure others know how to obtain assistance and operate the craft. In Boston a sailor knocked overboard by the boom died in full sight of the land and other boats and the person left aboard didn't know how to use the radio.

[10]

Boom accidents happen to the best sailors too, a quick Google search will link to many YouTube videos like this.

http://www.sail-world.com/Australia/Platino-rescue---Top-boatbuilder-named-as-dead-crew-member/145551

Videos on boom brake installation:

https://www.youtube.com/watch?v=-5TNkdoV6hE&feature=youtu.be

https://youtu.be/YOgubkfWhYk

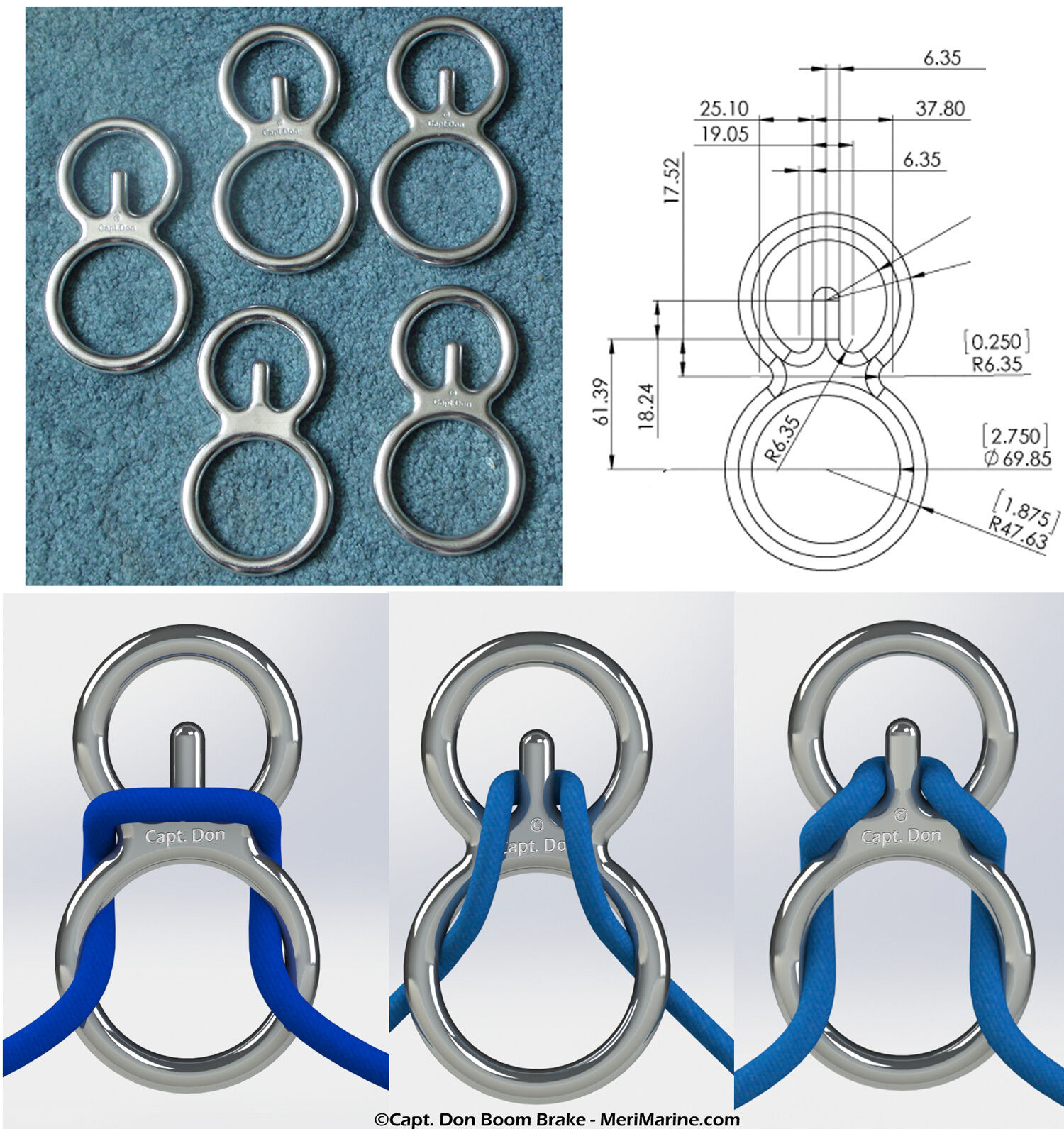

I have always dreamed of sailing the world and started the journey to fulfill my dream by going to sea full time for over 3 years on commercial vessels and getting certified as a M5 Captain and engineer. Friends asked me to make a boom brake that did not ruin a cruiser's budget. Well, after about a year of testing various hand made samples I am happy to say that I can now offer a boom brake that is made from ½ in 316L stainless steel, not aluminum. It is also about 20 % bigger than a climbers 8 being 6 ¾” long and 3 3/4” wide with a center pin for increased friction if required. Remember that the mast and boom absorb most of the sail loading so this boom brake can be used on a sail with a loading far in excess of the approximate 9800 pounds yield strength of the boom brake.

How big is the shackle on your vang and traveler? Typically those shackle bolts are smaller than 1/2" diameter and see more loading than the boom brake. If you trust them, you can trust our brake. :-) We also offer a larger boom brake through our web site at merimarine / dreamgreen for boats 38 ft and above.

Note:

Friction line can be most high tech lines. The breaking strength

of 3/8" Sta-Set = 5100lb, 1/2" Sta-Set = 9200lb.

Here is an online calculator that reveals sail loading:

http://www.harken.com/MainsheetLoading/

I

t is also better value compared to typically 0 or more for other options. These are not available in stores although I have had numerous requests but that means I would have to raise the price and eliminate many buyers who are also on a shoe string budget. Your support goes directly to helping my wife and I fix our boat and hopefully fulfill our dream of sailing.

The brake can be attached directly to the end of the Vang at the boom or to a bail in the boom track aft of the Vang or to a line wrapped around the boom but the best is to rig by attaching it to a line running under the boom so the load is divided over 2 attach points preferably a third of the length of the boom apart. This eliminates any boom point loading and keeps the boom under compression. See images of a Catalina 27 rigged this way.

It is often easier to attach the friction line to the top of the shroud turn buckles. see images. This provides the clearance to prevent the friction line rubbing on the coach roof which can cause changes in line length thus changes in tension and friction. One side can be run back to the cockpit for adjustment via a block and clam cleat at one shroud base. To avoid that extra line back to the cockpit a set of blocks with cleat can be attached to a shroud turn buckle and to one end of the friction line to provide tension adjustment. See the Bristol 32 installation link above. Once set it should require little adjustment for changes in wind strength.

I put together a short video of our boom brake used on a Catalina 27 and of course included some dolphins.

http://youtu.be/GGWI9OqsDFk

Remember:

1/ You do not need to use the winch to tighten the friction line, hand tighten is often enough.

2/ A change of only an inch in the friction line tension makes a big difference. As the boom swings the friction line length will change and thus the location of the boom brake is important to minimize this change. If in doubt about position please do not hesitate to contact me and I can do some calculations in a spreadsheet to show what impact your vang, shroud, boom arc and boom brake locations will have.

3/ If you find that you have a nice moving boom swing in one direction but not the other then try tying both ends off at the top of the shroud base turn buckles or put a block and cam cleat on one side. It seems some folk have a line with too much stretch and when the one side leads back to the cockpit via a block more stretch occurs on this side causing this problem. This problem has also occurred when the boom brake was placed too far aft on the boom, typically attaching about one third aft the length of the boom is good.

4/ If the brake jams, you might have too many friction line loops in the brake, change to match the images above, the geometry needs to be adjusted or your friction line is too thick. Start with a friction line that is approximately 3/8" diameter or even less on small boats that are in the low 20 ft range or smaller. It is always best to begin with a low friction setup and if it works but is loose try a slight change in tension before changing to a thicker line.

I created a free spreadsheet that can help optimize your boom brake placement.

dreamgreen.org/images/Boat-Parts/boom_brakes/Spreadsheet.xls

All you need to input is these dimensions in inches:

1/ Height of boom above anchor pt such as aft shroud turn buckles

2/ Horizontal Length between anchor pts

3/ Attach pt of vang to boom from gooseneck

4/ Distance of anchor pt aft of gooseneck

If you need any help interpreting the data contact me. The file can also be opened with Open Office.

Hope this helps.

Capt. Don

Comments:

Joe Anshien 2014-05-01 : Used the boom break on delivery from Martinique to Annapolis. Worked well.

Rodney Wood 2014-8-20 : I have an old IOR 1 ton warhorse with a fractional rig (rather long boom).

The Boom Brake worked great during the Summer Social buoy races with novice/passengers on board on the down wind legs.

Peter Puky : Don, suspending your brake from the boom ends turns the entire boom into a "compression post"! This makes the boom bullet proof! A very strong method of diverting the energy. As a rigger (historic = 25 years ago) I love it!! I purchased 3, one for me and the others for members of the WORLD CRUISING CLUB team.

Steve Kratchman: I only went out the day before pulling for winter but come spring I will experiment with my line sizes, however, I do have a 3/8 line now and that did work well enough. The mainsheet went over quickly but did not bang against the stops as it would have normally. So I am very pleased with my setup although now I have it tied off at the strbrd inboard shroud turnbuckle and am using the cam cleat block at the port inboard turnbuckle. It does make it quicker for testing tensions.

'87 39-2 Pearson, SOLOMONS MARINA, MD

Ed Martin: After some initial difficulty and testing I followed Don's calculations and rigged the boom brake 48 inches aft of the Gooseneck on my Bristol 32 and it works great with the same friction when the boom swings both sides, slowing it down nicely to a comfortable speed where no one is going to get hurt but not too tight so avoiding any excess load on the boom.

Gavin Smith 2017-03-30 01:30

Best bang for your buck when it comes to boom brakes. Easy to rig and use. I am a single hander and need all the help I can get when gybing Renaissance. Don's boom brake has decreased the potential for a damaging accidental gybe and made gybing on a windy day a lot less stressful! I have sailed with a end boom preventor for many years and the boom brake is a big step forward in my downwind gear and less expensive than most upgrades.

Skip Mortensen 2017-01-15 02:20

Used a mountaineering figure eight belay device for two seasons and it worked OK - This boom break is FAR SUPERIOR and has such a high polish that it does not burn up lines nearly as fast - Installed on an Irwin 10/4; 7,000 lb displacement dry and empty.

Massimo DellAria 2016-02-19 19:43

I had never used a boombrake. Before using it, endless bumps? I wish I could have recorded the audio- an incredible series of screams, grunts, and expletives, lots of expletives not to mention some very scary sounds that should never come to a boat.

I sail solo a lot and now I do so in greater safety and with no strain on my rigging. By the way I have a Bristol 32. One more thing, very important! This man has a sens e of ETHICS that are rarely met anymore. For that, and for his skills I say THANK YOU!!!!